SOLUTIONS AND EQUIPMENTS

WATER TREATMENT

STATION

Water treatment encompasses several technologies that provide quality water to guarantee public supply. Formed of a responsible system for clarifying surface or underground water, where changes in organoleptic, physical, chemical characteristics of water, transform contaminated water in drinking water, suitable for human consumption.

SEWAGE TREATMENT

STATION

The effluents from the industrial production chain and residential sewage presents diversified compositions with numerous pollutants harmful to the environment. As a way of reducing the environmental impacts caused by the discharge of wastewater, Bio G offers efficient sewage and effluent treatment systems.

DAF

The Dissolved Air Flotation (DAF) is an equipment that can be used in the treatment of domestic and industrial effluents. Its possible to install it for primary level treatment, solid-liquid separation replacing sedimentation and at the tertiary level for polishing and nutrient removal of the effluent.

SCREW PRESS

The press is an equipment designed for the separation of solid and liquid particles with low operational cost. By the principle of gravity separation and mechanical pressing, it is capable of separating the liquid phase of the solid phase into a wide range of industrial products, treatment station sludges, industrial wastes, miscellaneous solid, vegetable and others.

DECANTER

Centrifugal decanters provide separation of solid and liquid phases from very effective way. They are versatile equipment capable of operating in variable flow rates in the most diverse processes. Features a variety of sizes and models that meet different types of applications.

TRIDECANTER

The GRATT Tridecanter is the pioneer and the best equipment of the national market with a very high performance. It has unique characteristics and is a reference of equipment in its category, resulting in a three-phase separation (two liquids and a solid) with the higher efficiency and best yield on the market.

CENTRIFUGE

Designed to separate the phases through centrifugal force, Gratt Centrifuges, depending on the model, reach up to 12,000 times the gravitational acceleration, providing continuous and satisfactory clarification, separation or purification in applications with less than 3% of solids content.

DRYING SYSTEM

Gratt steam dryers have been developed for drying sanitary and industrial waste, as well as various by-products of animal and vegetable origin. After dehydration, the waste can be used in the generation of thermal energy through burning, organic fertilizers, and rations supply, etc. The systems are supplied partially or completely, according to the customer's needs.

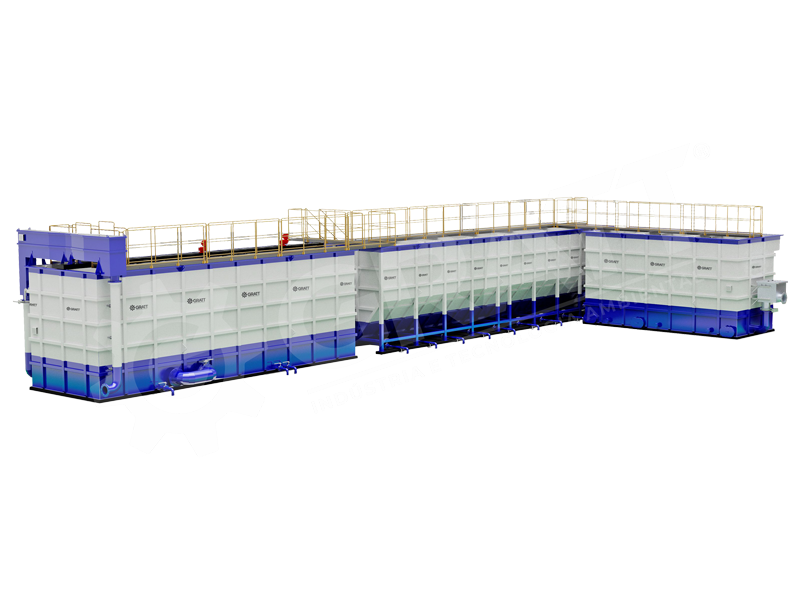

VITRIFIED STEEL TANKS

GRATT vitrified steel tanks are tanks made of bolted steel plates. The carbon steel plates receive a vitrified coating on their inner and outer surfaces. The process of formation of this layer occurs by the application of a bottom layer of nickel oxide and a glass finish, both of which are cast to the steel, at a temperature of 850 °C, and because it is a fusion to steel and not a paint, the strength and durability of the coating is extremely high, giving a 30 year compound life.